- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Conductive foil PCB shielding gasket

- Home

- PCB shielding

- PCB shielding gaskets

- Conductive foil PCB shielding gasket

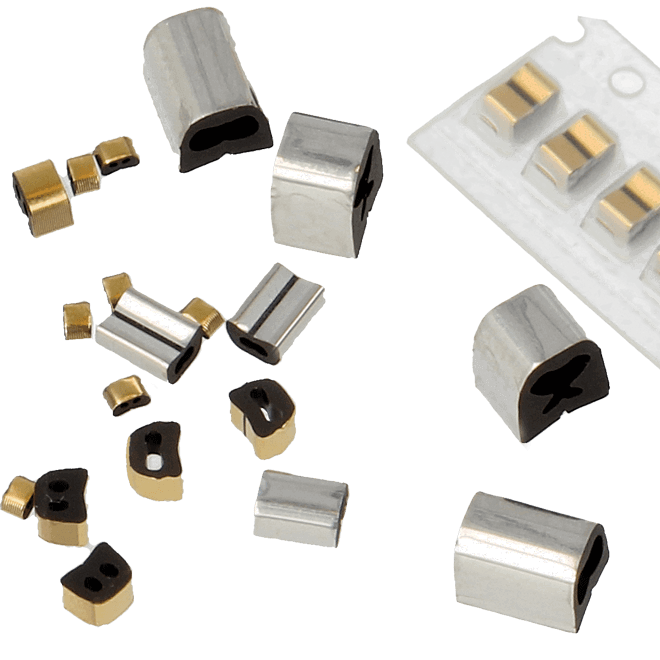

1550 series has good elastic recovery and electric properties, so it offers not only cushion properties, but also electrical connecting between electrical objects including PCB. It is useful for EMI/ESD/RF countermeasure, electrical grounding and connecting as EMI gasket and/or electric connector. It consists of conductive film, elastic adhesive and elastomer tube, so it is not broken and deformed like metal fingers. There are many sizes and options to meet various customers demands and needs.

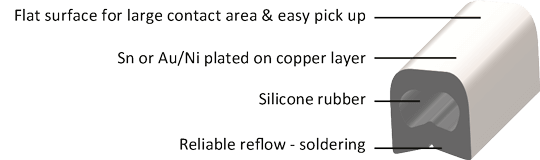

General structure

Metal clip VS 1550

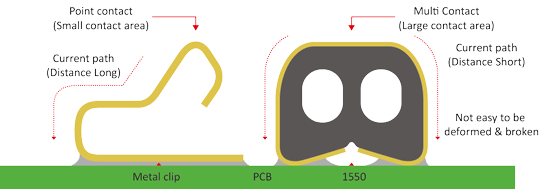

Optional on request

The 1550 gasket is standard delivered with one hole. Optional is a version with two holes in the gasket. Keep in mind that because of the two holes the gasket can be stiff / harder and less easy to compress.

Technical specifications

| Standard-Type (Tin) | Gold-Type (Au/Ni) | |

|---|---|---|

| Copper Layer (inside) | Standard performance | High performance |

| Plating (surface) | Sn (Tin) | Au/Ni |

| Plating on the copper edge | None | Yes Au/Ni |

| Reliability | Good | Best |

| Example of P/N | 1550-W-H-L-S | 1550-W-H-L-G |

| Main applications | Economic price, home applications | Automotive, industrial & military |

| Re-flow soldering Temp. | Max 250 °C | Max 270 °C |

| Max. rework | 1 time | 3 times |

| Price | $ | $$ |

| These values are measured under laboratory conditions. In other situations results may differ. Please read our Guarantee. |

||

Application

- Smartphone

- Automotive

- TV

- Tablet

- PC

- LCD panel

- Navigation for electrical connection

- Grounding

Characteristics

- Surface mount technology (SMT) compatible

- Lowest electric resistance (typical 0.06 Ω)

- Excellent elasticity & low compression force

- Not easily deformed & broken by external force

- Large contact area

- Solder protection line exist

- Sizes from small to big with various options

- Proper for mass production & re-work available

- Halogen-free, EU-RoHS compliant, non-flammable

Properties

| Materials | Silicone Rubber, Silicone adhesive, polyimide film, Sn or AU/NI plated copper layer |

|---|---|

| Width | 0.45 mm ∼ |

| Height | 1.2 mm ∼ |

| Compression Ratio | Typical 10% ∼ 40% compression of original height |

| Operation Temperature | -35 °C ∼ 160 °C |

| Resistance Vertical/Surface | Typical 0.06 Ω/ typical 0.06 Ω |

| Elastomer hardness | Shore A 50, shore A 65 |

| Recovery ratio (25%*500times) | Typical 90% of original height (depends on size) |

| Soldering Strength | Depends on sizes (long length provides strong soldering strength) |

| Abrasion Test | No metal dust after rubbing with PP tape (2 kg roller / 10 cycles) |

| Thermal shock | Change ratio of resistance & elasticity is lower than 10% (-40°C*0.5hr ↔ 85°Cx0.5hr*100cycles) |

| High temperature/humidity | Change ratio of resistance & elasticity is lower than 10% (85°C / 85% RH / 100hrs) |

| Salt spray | Change ratio of resistance & elasticity is lower than 10% (KS D 9502, 5% NaCl, 35°C/12hrs) |

| Flammability | Over UL 94 V-1 (UL file No. E250169) |

| Environment | Halogen Free, EU-RoHS compliant, lead-free |

| Reflow Soldering | max. 250 °C for Sn plating, max. 270 °C for Au/Ni plating. |

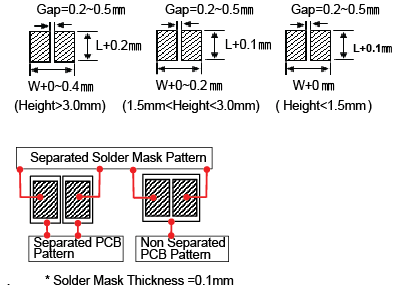

| Recommend Solder pattern |  |

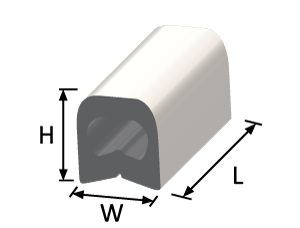

Part number dimensions

| Part number | W | H | L | Part number | W | H | L | Part number | W | H | L |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1550-2.0-0.45-1.0 | 2.0 | 0.45 | 1.0 | 1550-2.0-3.0-1.5 | 2.0 | 3.0 | 1.5 | 1550-4.0-5.5-5.0 | 4.0 | 5.5 | 5.0 |

| 1550-2.0-0.45-1.5 | 2.0 | 0.45 | 1.5 | 1550-2.0-3.0-1.8 | 2.0 | 3.0 | 1.8 | 1550-5.0-5.5-3.0 | 5.0 | 5.5 | 3.0 |

| 1550-1.6-0.6-0.8 | 1.6 | 0.6 | 0.8 | 1550-2.5-3.0-1.5 | 2.5 | 3.0 | 1.5 | 1550-5.0-5.5-4.0 | 5.0 | 5.5 | 4.0 |

| 1550-2.0-0.6-1.0 | 2.0 | 0.6 | 1.0 | 1550-2.5-3.0-2.0 | 2.5 | 3.0 | 2.0 | 1550-6.0-5.5-4.0 | 6.0 | 5.5 | 4.0 |

| 1550-1.6-0.7-0.8 | 1.6 | 0.7 | 0.8 | 1550-3.0-3.0-1.5 | 3.0 | 3.0 | 1.5 | 1550-6.0-5.5-8.0 | 6.0 | 5.5 | 8.0 |

| 1550-2.0-0.7-1.0 | 2.0 | 0.7 | 1.0 | 1550-3.0-3.0-2.0 | 3.0 | 3.0 | 2.0 | 1550-4.0-6.0-3.0 | 4.0 | 6.0 | 3.0 |

| 1550-1.2-0.8-0.8 | 1.2 | 0.8 | 0.8 | 1550-3.5-3.0-2.5 | 3.5 | 3.0 | 2.5 | 1550-4.0-6.0-5.0 | 4.0 | 6.0 | 5.0 |

| 1550-1.6-0.8-0.8 | 1.6 | 0.8 | 0.8 | 1550-4.0-3.0-3.0 | 4.0 | 3.0 | 3.0 | 1550-4.5-6.0-2.5 | 4.5 | 6.0 | 2.5 |

| 1550-1.4-0.9-0.8 | 1.4 | 0.9 | 0.8 | 1550-4.0-3.0-5.0 | 4.0 | 3.0 | 5.0 | 1550-4.5-6.0-4.0 | 4.5 | 6.0 | 4.0 |

| 1550-1.6-0.9-0.8 | 1.6 | 0.9 | 0.8 | 1550-4.0-3.0-8.0 | 4.0 | 3.0 | 8.0 | 1550-4.5-6.0-6.0 | 4.5 | 6.0 | 6.0 |

| 1550-1.2-1.0-0.8 | 1.2 | 1.0 | 0.8 | 1550-5.0-3.0-3.0 | 5.0 | 3.0 | 3.0 | 1550-5.0-6.0-3.0 | 5.0 | 6.0 | 3.0 |

| 1550-1.6-1.0-0.8 | 1.6 | 1.0 | 0.8 | 1550-5.0-3.0-4.0 | 5.0 | 3.0 | 4.0 | 1550-5.0-6.0-4.0 | 5.0 | 6.0 | 4.0 |

| 1550-1.4-1.1-0.8 | 1.4 | 1.1 | 0.8 | 1550-3.0-3.5-1.5 | 3.0 | 3.5 | 1.5 | 1550-5.0-6.5-3.0 | 5.0 | 6.5 | 3.0 |

| 1550-1.6-1.1-0.8 | 1.6 | 1.1 | 0.8 | 1550-3.0-3.5-2.0 | 3.0 | 3.5 | 2.0 | 1550-5.0-6.5-8.0 | 5.0 | 6.5 | 8.0 |

| 1550-1.6-1.2-0.8 | 1.6 | 1.2 | 0.8 | 1550-4.0-3.5-2.0 | 4.0 | 3.5 | 2.0 | 1550-6.0-6.5-4.0 | 6.0 | 6.5 | 4.0 |

| 1550-4.0-3.5-3.0 | 4.0 | 3.5 | 3.0 | 1550-6.0-6.5-8.0 | 6.0 | 6.5 | 8.0 | ||||

| 1550-1.6-1.5-0.8 | 1.6 | 1.5 | 0.8 | 1550-4.0-3.5-5.0 | 4.0 | 3.5 | 5.0 | 1550-8.0-6.5-4.0 | 8.0 | 6.5 | 4.0 |

| 1550-3.0-1.5-2.0 | 3.0 | 1.5 | 2.0 | 1550-3.0-4.0-2.0 | 3.0 | 4.0 | 2.0 | 1550-5.0-7.0-3.0 | 5.0 | 7.0 | 3.0 |

| 1550-3.0-1.5-4.0 | 3.0 | 1.5 | 4.0 | 1550-4.0-4.0-2.5 | 4.0 | 4.0 | 2.5 | 1550-8.0-7.0-4.0 | 8.0 | 7.0 | 4.0 |

| 1550-1.7-1.6-3.6 | 1.7 | 1.6 | 3.6 | 1550-4.0-4.0-3.0 | 4.0 | 4.0 | 3.0 | 1550-5.0-7.5-3.0 | 5.0 | 7.5 | 3.0 |

| 1550-1.6-1.8-0.8 | 1.6 | 1.8 | 0.8 | 1550-4.0-4.0-5.0 | 4.0 | 4.0 | 5.0 | 1550-6.0-7.5-4.0 | 6.0 | 7.5 | 4.0 |

| 1550-2.0-1.8-1.0 | 2.0 | 1.8 | 1.0 | 1550-4.0-4.0-6.0 | 4.0 | 4.0 | 6.0 | 1550-6.0-7.5-8.0 | 6.0 | 7.5 | 8.0 |

| 1550-2.0-1.8-1.25 | 2.0 | 1.8 | 1.25 | 1550-5.0-4.0-3.0 | 5.0 | 4.0 | 3.0 | 1550-8.0-7.5-4.0 | 8.0 | 7.5 | 4.0 |

| 1550-2.0-1.8-1.5 | 2.0 | 1.8 | 1.5 | 1550-5.0-4.0-4.0 | 5.0 | 4.0 | 4.0 | 1550-8.0-8.0-4.0 | 8.0 | 8.0 | 4.0 |

| 1550-2.5-2.0-2.0 | 2.5 | 2.0 | 2.0 | 1550-8.0-4.0-4.0 | 8.0 | 4.0 | 4.0 | 1550-6.0-8.5-8.0 | 6.0 | 8.5 | 8.0 |

| 1550-3.0-2.0-2.0 | 3.0 | 2.0 | 2.0 | 1550-3.0-4.5-3.0 | 3.0 | 4.5 | 3.0 | 1550-8.0-8.5-4.0 | 8.0 | 8.5 | 4.0 |

| 1550-3.0-2.0-4.0 | 3.0 | 2.0 | 4.0 | 1550-4.5-4.5-6.0 | 4.5 | 4.5 | 6.0 | 1550-5.0-9.0-6.0 | 5.0 | 9.0 | 6.0 |

| 1550-2.0-2.2-1.5 | 2.0 | 2.2 | 1.5 | 1550-5.0-4.5-3.0 | 5.0 | 4.5 | 3.0 | 1550-6.0-9.0-8.0 | 6.0 | 9.0 | 8.0 |

| 1550-2.5-2.3-1.5 | 2.5 | 2.3 | 1.5 | 1550-5.0-4.5-6.0 | 5.0 | 4.5 | 6.0 | 1550-6.0-9.5-8.0 | 6.0 | 9.5 | 8.0 |

| 1550-2.6-2.4-3.6 | 2.6 | 2.4 | 3.6 | 1550-5.0-4.5-8.0 | 5.0 | 4.5 | 8.0 | 1550-6.0-10.0-8.0 | 6.0 | 10.0 | 8.0 |

| 1550-2.6-2.4-8.0 | 2.6 | 2.4 | 8.0 | 1550-6.0-4.5-4.0 | 6.0 | 4.5 | 4.0 | 1550-8.0-10.0-4.0 | 8.0 | 10.0 | 4.0 |

| 1550-2.0-2.5-1.5 | 2.0 | 2.5 | 1.5 | 1550-6.0-4.5-8.0 | 6.0 | 4.5 | 8.0 | 1550-6.0-10.5-5.0 | 6.0 | 10.5 | 5.0 |

| 1550-2.5-2.5-2.0 | 2.5 | 2.5 | 2.0 | 1550-3.5-5.0-2.5 | 3.5 | 5.0 | 2.5 | 1550-6.0-10.5-8.0 | 6.0 | 10.5 | 8.0 |

| 1550-3.0-2.5-1.5 | 3.0 | 2.5 | 1.5 | 1550-4.0-5.0-3.5 | 4.0 | 5.0 | 3.5 | 1550-6.0-11.5-8.0 | 6.0 | 11.5 | 8.0 |

| 1550-3.0-2.5-2.0 | 3.0 | 2.5 | 2.0 | 1550-4.0-5.0-5.0 | 4.0 | 5.0 | 5.0 | 1550-6.0-12.5-8.0 | 6.0 | 12.5 | 8.0 |

| 1550-3.0-2.5-4.0 | 3.0 | 2.5 | 4.0 | 1550-4.0-5.0-5.0 | 4.0 | 5.0 | 5.0 | 1550-6.0-13.0-8.0 | 6.0 | 13.0 | 8.0 |

| 1550-4.0-2.5-3.0 | 4.0 | 2.5 | 3.0 | 1550-4.5-5.0-2.5 | 4.5 | 5.0 | 2.5 | 1550-6.0-13.5-8.0 | 6.0 | 13.5 | 8.0 |

| 1550-4.0-2.5-5.0 | 4.0 | 2.5 | 5.0 | 1550-5.0-5.0-2.5 | 5.0 | 5.0 | 2.5 | 1550-6.0-14.5-8.0 | 6.0 | 14.5 | 8.0 |

| 1550-5.0-2.5-3.0 | 5.0 | 2.5 | 3.0 | 1550-5.0-5.0-3.0 | 5.0 | 5.0 | 3.0 | 1550-6.0-15.5-8.0 | 6.0 | 15.5 | 8.0 |

| 1550-5.0-2.5-4.0 | 5.0 | 2.5 | 4.0 | 1550-6.0-5.0-8.0 | 6.0 | 5.0 | 8.0 | ||||

| 1550-2.0-2.8-1.8 | 2.0 | 2.8 | 1.8 | 1550-8.0-5.0-4.0 | 8.0 | 5.0 | 4.0 | ||||

| Holland shielding systems BV have got more than 100 kinds of 1550 series Film over Rubber PCB shielding gaskets for many applications and usages. Please contact our engineer for your selection. S: Standard (tin), G = Gold (Au/Ni) |

|||||||||||